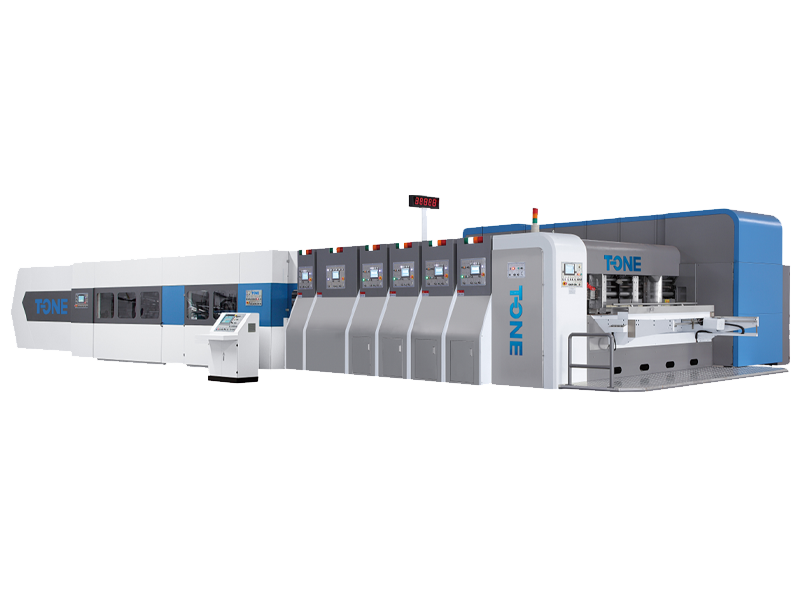

TD high speed water-based printing slotting die-cutting stacking machine

The whole machine adopts the international advanced design concept, through the European CE certification, in accordance with the European and American manufacturing standards, to Taiwan's own years of production experience and design and manufacturing.

Features of the whole machine:

The whole machine adopts the international advanced design concept, through the European CE certification, in accordance with the European and American manufacturing standards, to Taiwan's own years of production experience and design and manufacturing.

The transmission gear is imported, the transmission gear is hardened and ground, and the Rockwell hardness is> 60 degrees.

· The gap adjustment of conveying roller, embossing roller, rubber roller and anilox roller adopts self-locking structure.

Independent computer control, can store common orders, change orders quickly, easy to operate. Automatic zero, automatic reset.

Classification:

Key words:

TD high speed water-based printing slotting die-cutting stacking machine

Technical parameters

Slide the table left and right to view all parameters

Paper feeding unit

·Continuous or separate paper feed (with counter).

·The leading edge paper feed increases the suction flow, and the paper feed is more stable and accurate.

·Dust removal device: brush and fan can remove paper scraps on the surface of cardboard.

·The gap adjustment of the paper-pulling rubber roller adopts a self-locking structure.

Printing Unit

·The reel hanging plate and ratchet locking device make the hanging plate more accurate.

·Roll-to-roll transfer printing.

·Automatically switch the cleaning device to make the ink recovery more thorough.

·The gap adjustment of conveying roller, embossing roller, rubber roller and anilox roller adopts self-locking structure.

·Optional single scraper inking system, improve printing quality, simple and convenient operation(optional).

slotting unit

·Single-axis double-knife slotting, box height adjustment adopts internal tooth structure, so that lubricating oil is not easy to pollute the carton.

·The slotted cutter seat has a transverse structure, and the screw rod is matched with the linear guide rail to make the movement more flexible and accurate.

·The upper knife seat and the lower knife seat are linked by the transmission shaft, which keeps the upper and lower knives aligned when moving, and prolongs the life of the tool.

·The slotted cutter seat clearance, preloading and indentation clearance adjustment adopt self-locking structure.

·The height adjustment of the slotting tool box has an anti-collision protection device, which will not damage the machine.

·The elastic corner cutter structure can cut three or five layers of cardboard without adjustment and is easy to operate.

Die-cutting unit

·Mechanical spiral reversing of rubber pad roller50mmswimming lateral structure.

·Electric adjustment of the gap between the rubber pad roller and the knife roller.

·The self-locking structure is adopted for the adjustment of the conveying roller.

·The rubber pad roller compensation is driven by an independent motor to control the speed of the rubber pad roller, and the compensation range is ±3mm.

·The rubber pad roller shall be cut and flattened to keep the surface of the rubber pad roller flat.

Oscillating Scrap Machine & Automatic Stacker

·Waste removal department adopts independent motor drive, vibration shaft-The axis has three dither points to accelerate the dither frequency and improve the dither effect.

·The jitter belt adopts imported cylindrical high-elastic belt, which has good elasticity and does not damage the cardboard. The vibration belt drive is controlled by an independent speed regulating motor, which is convenient for speed modulation and ensures the jitter stroke.

·The back end of the waste removal part is provided with a strong blowing and brush device to prevent the waste paper from returning to the surface of the cardboard, so as to achieve the best effect of waste removal.

·StackerThe paper connection can be operated automatically or manually.

·The air pressure action paper receiving pallet, when the cardboard is stacked to a predetermined height, the paper receiving pallet automatically extends to hold the cardboard.

·The belt of the paper arm is individually adjusted for tightness, and is not limited by the length of the belt.

Main technical parameters

| Model | TD920 | TD1224 | TD1228 | TD1426 | TD1628 | TD1632 | TD2236 | TD2242 | TD2636 |

| Maximum mechanical speed (sheets/min) | 300 | 250 | 230 | 200 | 180 | 180 | 140 | 130 | 100 |

| Maximum paper feed size (mm) | 900 × 2000 | 1200 × 2400 | 1200 × 2800 | 1400 × 2600 | 1600 × 2800 | 1600 × 3200 | 2200 × 3600 | 2200 × 4200 | 2600 × 3600 |

| Minimum feed size (mm) | 260 × 600 | 320 × 600 | 320 × 600 | 420 × 600 | 450 × 600 | 450 × 600 | 500 × 700 | 500 × 700 | 500 × 700 |

| Sheet size (mm) | 1200 × 2000 | 1500 × 2400 | 1500 × 2800 | 1700 × 2600 | 1900 × 2800 | 1900 × 3200 | 2500 × 3600 | 2500 × 4200 | 2800 × 3600 |

| Maximum printing area (mm) | 900 × 1960 | 1200 × 2360 | 1200 × 2760 | 1400 × 2560 | 1600 × 2760 | 1600 × 3160 | 2200 × 3560 | 2200 × 4160 | 2500 × 3560 |

| Minimum slotting interval (backcut)(mm) | 240 × 65 × 240 × 65 | 260 × 65 × 260 × 65 | 260 × 65 × 260 × 65 | 260 × 65 × 260 × 65 | 260 × 65 × 260 × 65 | 260 × 65 × 260 × 65 | 360 × 95 × 360 × 95 | 360 × 95 × 360 × 95 | 360 × 95 × 360 × 95 |

| Minimum slotting interval (positive)(mm) | 130 × 130 × 130 × 130 | 130 × 130 × 130 × 130 | 130 × 130 × 130 × 130 | 130 × 130 × 130 × 130 | 130 × 130 × 130 × 130 | 130 × 130 × 130 × 130 | 150 × 150 × 150 × 150 | 150 × 150 × 150 × 150 | 150 × 150 × 150 × 150 |

| Maximum slotting depth (mm) | 250 | 300 | 300 | 350 | 400 | 400 | 700 | 700 | 700 |

Due to technical needs, product specifications or mechanical structure changes a small amount of improvement, without notice, subject to the contract parameters

Product Consulting

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Recommend Products