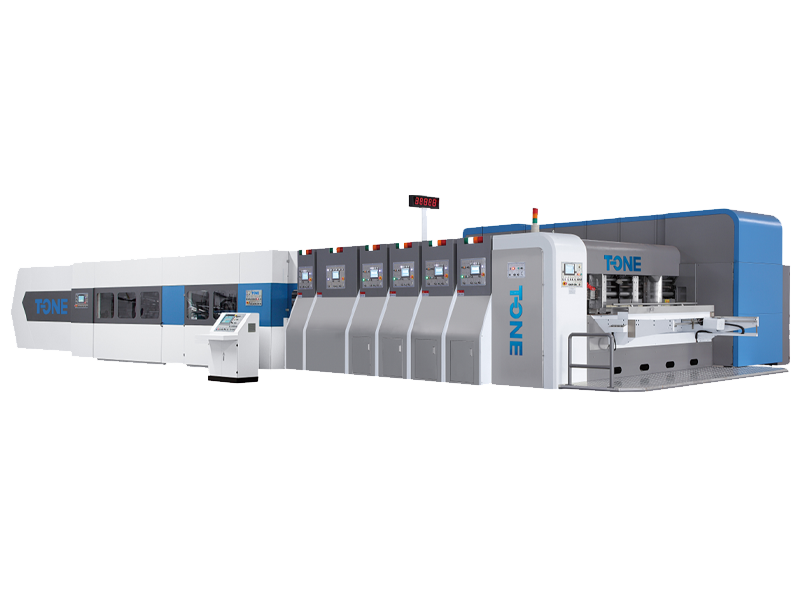

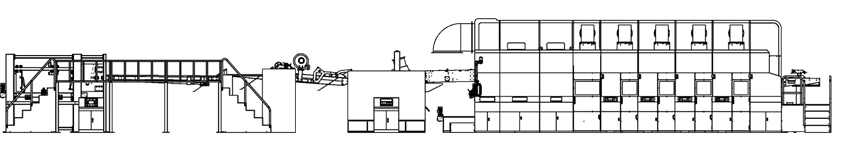

T-BF fixed lower printing slotting die-cutting points pushing and stacking machine

The overall use of new industrial design appearance, in accordance with European and American standards design.

Features of the whole machine:

· The overall use of new industrial design appearance, in accordance with European and American standards design.

Full servo drive does not stop the machine for plate change, quick order change, convenient operation, high efficiency and high yield.

The lower printing fixed printing, the United States solar vacuum adsorption transmission; The whole machine is stable, the adsorption paper is smooth, the operation and maintenance are convenient, and the printing quality and overprinting precision are high.

The industry's first handheld central control panel and each unit data real-time transmission, production control, remote maintenance is convenient.

· The slotting adopts double slotting structure, which can be suitable for various box types and various orders.

The whole machine adopts the German Siemens system, the key electronic components adopt the imported brand, the key parts adopt the original parts of the American Sun Company, and are equipped with remote blocks, the equipment has high precision, and the equipment is efficient, safe and stable.

Classification:

Key words:

T-BF fixed lower printing slotting die-cutting points pushing and stacking machine

Technical parameters

Slide the table left and right to view all parameters

Paper feeding unit

·Variable frequency control vacuum airflow and pressure to match the cardboard size.

·The US sun leading edge paper feeding wheel box and paper feeding platform ensure paper feeding accuracy and paper feeding stability for a long time.

·The front baffle and the left and right baffles adopt linear guide rails to move horizontally, with stable regulation and a roller shutter type protective cover.

·The double-layer rubber surface of the paper-pulling rubber roller is not easy to damage the cardboard and is wear-resistant.

·Widened dust removal system, the dust collection device can lift 150mm as a whole, which is convenient for disassembly and assembly of multiple groups of brushes and electrostatic removal devices, perfect dust removal and cleaner cardboard surface. Equipped with anti-jam device

Printing Unit

· The United States sun "under the printing type" vacuum adsorption wheel box conveying, paper feeding wheel surface for ceramic, increase wear resistance and life.

The reel hanging plate and ratchet locking device make the hanging plate more accurate.

· Lenglong type plate changing structure, plate changing and ink changing without stopping the machine.

· New ink-saving cycle ink supply system-Automatic switching cleaning device, so that ink recovery more thoroughly

· The wind box adopts permanent magnet fan, which is more energy-saving than traditional fan10% Above, there is a dust collection system.

· Optional roller inking system and sun(SUN)Scraper inking system, improve printing quality, simple and convenient operation.

Drying unit

Main control computer regulation, thermostat adjustment display.

· Hot air circulation drying mode, adjustable temperature value, safety and energy saving

Optional infrared orUV Drying method to ensure the quality of glazing.

Line pressing unit

· Independent pressure line unit, using servo drive.

· Pressure line transverse adjustment mechanism, make the movement more flexible and accurate.

· Pre-pressure wheel, pressing wheel, slotting knife seat transverse position, using computer and electric digital control.

Adopt 1:1 large pressing line structure, which has low requirements for cardboard conditions and does not damage the cardboard, making the pressing line effect more perfect and the forming more beautiful.

slotting unit

· Double-axis slotting, servo-driven.

· The slotted knife seat transverse adjustment mechanism: the use of screw rod with linear guide rail, so that the movement is flexible and accurate. The upper tool seat and the lower tool seat adopt the synchronous linkage of the transmission shaft, and the tool life is long.

· With paper wheel, slotted knife seat transverse position, using computer and electric digital control.

· Optional single-axis double-knife slotting, double destruction wheel slotting unit.

There is a chopping paper structure in front of the trimming knife.

· The paper shovel knife adopts the principle of gravity, which is not affected by external force and reduces wear.

Die-cutting unit

· Independent servo motor drive, effectively reducing the vibration of the printing unit, printing more accurate.

The rubber pad roller compensation adopts independent servo drive to control the speed of the rubber pad roller, and mechanically reverses the 50mm swimming transverse structure to keep the speed of the rubber pad roller consistent with that of the die roller. Compensation range up

· American sun automatic mold repair, automatic compensation pad roller speed

High die cutting precision, waste cleaning efficiency increased by 25%.

Waste clearing unit

·The concussion part can be raised to facilitate plate changing and is provided with an anti-falling device.

The use of variable frequency drive, speed regulation, operation and control more convenient.

Two sections of high-frequency oscillation, clean and clean.

Three high-power fans blow paper scraps, strong decrumbs blowing, multiple auxiliary waste discharge.

Can do a three-die cut waste, to meet a variety of orders.

Points Stacking Unit

Four-segment servo drive to ensure accurate points.

Lifting type paper tray, conveying table according to the set number of belt output.

· Servo motor drive control, telescopic fork rod separation system.

The transmission platform can be electrically lifted and equipped with safety devices

The all-in-one machine of point stacking height can output both small stack points and large overall output.

|

Model Project |

T-BF1224 |

T-BF1228

|

T-BF1628

|

T-BF1632 |

|

Maximum Speed (Zhang) |

250 |

230 |

220 |

200 |

|

Maximum paper feed scale (mm) |

1200x2400 |

1200x2800 |

1600x2800 |

1600x3200 |

|

Minimum Paper Feed (mm) |

320x600 |

320x600 |

450x600 |

450x600 |

|

SPLIT PAPER FEETING (mm) |

1500x2400 |

1500x2800 |

1900x2800 |

1900x3200 |

|

Max. Printing (mm) |

1200x2360 |

1200x2760 |

1600x2760 |

1600x3160 |

|

Standard Plate Thickness (mm) |

7.2 |

7.2 |

7.2 |

7.2 |

|

Minimum slotting interval positive cutter (mm) |

260x65x260 x65 |

260x65x260x65 |

260x65x260x65 |

260x65x260x65

|

|

Minimum slotting interval positive cutter (mm) |

130x130x130x130 |

130x130x130x130

|

130x130x130x130 |

130x130x130x130

|

|

Maximum slotting depth (mm) |

300 |

300 |

400 |

400 |

Due to technical needs, product specifications or mechanical structure changes a small amount of improvement, without notice, subject to the contract parameters

Product Consulting

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Recommend Products