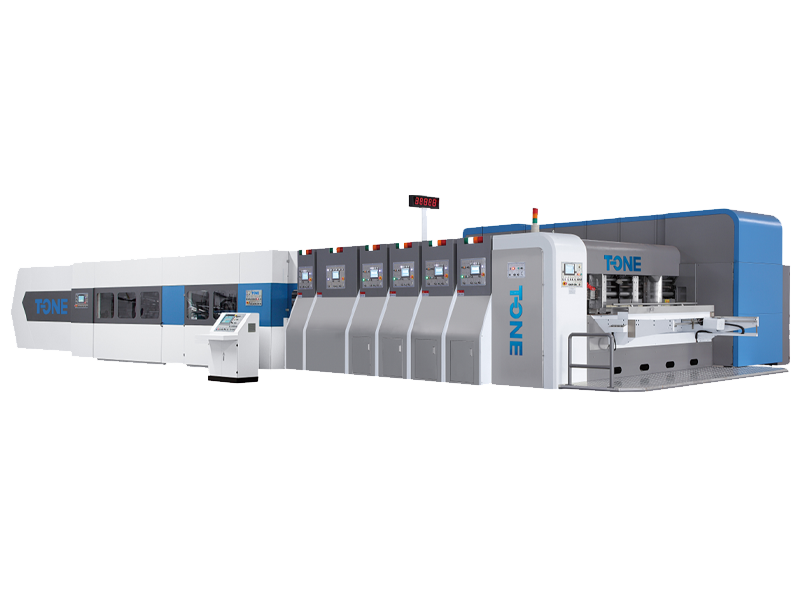

T-SC full servo high speed printing slotting die cutting machine

Each unit independent servo drive, more stable paper feeding, more stable operation, more accurate overprint, higher precision.

Features of the whole machine:

Each unit independent servo drive, more stable paper feeding, more stable operation, more accurate overprint, higher precision.

Reduce transmission wear and reduce failure rate.

Each unit of the whole machine is separated automatically or independently, which makes the operation more convenient, and the continuous bell warning when walking ensures the safety of the operator.

· All clearance adjustments are computer controlled, fast response.

· Remote maintenance management, online diagnosis troubleshooting.

· New industrial design, using new materials, technology fashion.

Classification:

Key words:

T-SC full servo high speed printing slotting die cutting machine

Technical parameters

Slide the table left and right to view all parameters

Each unit independent servo motor drive

Paper feeding unit

Multi-axis servo pressure-free paper feeding is adopted to reduce cardboard damage and keep cardboard pressure-resistant.

· Servo motor independent drive, vacuum transfer printing, accurate transfer cardboard.

· Electrostatic dust removal device, equipped with multi-row brush and dust suction fan to remove paper scraps on the surface of cardboard to improve printing quality.

Automatic protection device for host motor (when the machine is not locked, the host cannot start running)

Printing Unit

· Adopt vacuum adsorption conveying cardboard (the surface of the paper feeding wheel is ceramic, which increases wear resistance and prolongs life).

· Printing phase adjustment using servo motor drive, printing higher precision, faster.

· Optional imported advanced scraper ink supply system: scraper cavity body for non-metallic special material, never rust, easy to clean; can quickly replace the scraper blade. (Optional)

Each printing unit can be equipped with a small infrared drying device to improve printing quality (optional).

With high-pressure rapid automatic cleaning ink saving function.

Multi-color printing in the running state, not printing unit can stop running alone, energy saving.

Drying unit (optional IR independent infrared drying system)

According to the width of the cardboard, the infrared lamp can be controlled in sections to save energy.

The infrared drying method can quickly dry the water-based varnish on the surface of the printed matter to avoid the drag phenomenon during die cutting. At the same time, it also effectively improves the printing speed of the product and ensures the polishing quality.

slotting unit

· The new single-axis double-knife slotting, box height adjustment adopts internal tooth structure, so that the lubricating oil is not easy to pollute the carton.

· Slot cutter seat traverse servo adjustment mechanism: the use of screw rod with linear guide to make the movement more flexible and accurate.

Double destruction wheel slotting unit; The large line pressing structure is adopted to make the line pressing effect more perfect. The upper pressing wheel is wrapped with excellent glue on the outside without damaging the cardboard.

Die-cutting unit

· Rubber pad roller machinery 50mm reversing walking transverse structure.

The rubber pad roller compensation adopts independent servo drive to control the speed of the rubber pad roller, and the compensation range is 3.5mm.

· Rubber pad roller micro-mold system to keep the surface of the rubber pad flat.

The mold repair roller is made of emery material to make the die cutting smoother.

Main parameters:

|

Model |

T-SC920 |

T-SC924 |

T-SC1224 |

T-SC1228 |

T-SC1628 |

T-SC1632 |

|

Maximum mechanical speed (sheets/min) |

350 |

320 |

300 |

300 |

250 |

220 |

|

Maximum paper feed size (mm) |

900x2000 |

900x2400 |

1200x2400 |

1200x2800 |

1600x2800 |

1600x3200 |

|

Minimum feed size (mm) |

270x600 |

270x600 |

320x600 |

320x600 |

450x600 |

450x600 |

|

Sheet size (mm) |

1200x2000 |

1200x2400 |

1500x2400 |

1500x2800 |

1900x2800 |

1900x3200 |

|

Maximum printing area (mm) |

900x1960 |

900x2360 |

1200x2360 |

1200x2760 |

1600x2760 |

1600x3160 |

|

Minimum slotting interval (backcut)(mm) |

230x65x230x65 |

230x65x230x65 |

230x65x230x65 |

230x65x230x65 |

260x65x260x65 |

260x65x260x65 |

|

Minimum slotting interval (positive)(mm) |

130x130x130x130 |

130x130x130x130 |

130x130x130x130 |

130x130x130x130 |

130x130x130x130 |

130x130x130x130 |

|

Maximum slotting depth (mm) |

250 |

250 |

300 |

300 |

400 |

400 |

Due to technical needs, product specifications or mechanical structure changes a small amount of improvement, without notice, subject to the contract parameters

Product Consulting

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Recommend Products