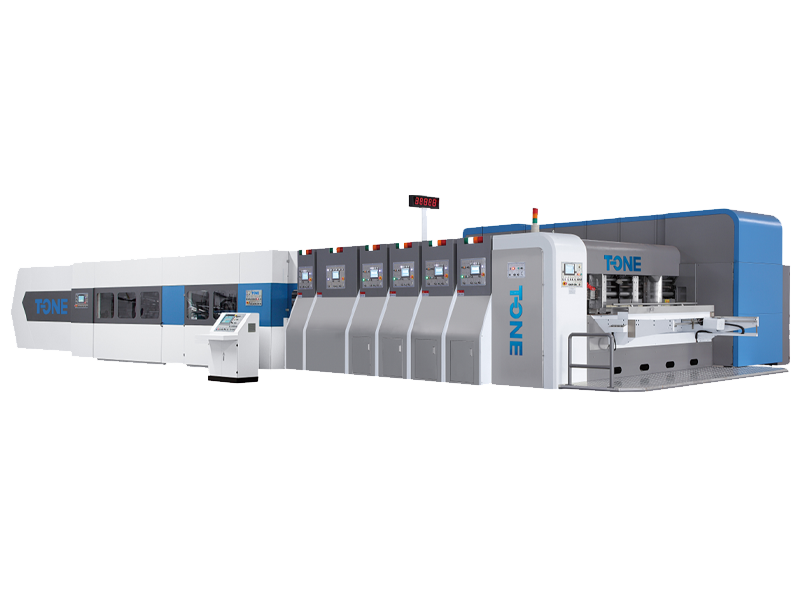

T-PC open and close type upper and lower printing die cutting machine

The whole machine is designed and manufactured according to high requirements, reliability and safety. It has passed the European CE certification and is optimized by combining Taiwan with many years of production experience.

Features of the whole machine:

The whole machine is designed and manufactured according to high requirements, reliability and safety. It has passed the European CE certification and is optimized by combining Taiwan with many years of production experience.

· The whole machine can be equipped with full servo drive, precise control, intelligent and efficient.

The whole machine adopts touch screen PLC control, which can store orders, change orders faster and more convenient to operate. The gap adjustment of conveying roller, embossing roller, rubber roller and anilox roller is controlled by electric PLC.

· Remote maintenance management, online fault diagnosis.

The upper and lower printing are synchronized, and the front and back printing are completed at one time.

Classification:

Key words:

T-PC open and close type upper and lower printing die cutting machine

Technical parameters

Slide the table left and right to view all parameters

Paper feeding unit

·Continuous or separate paper feed (with counter).

·The leading edge pressure-free paper feeding platform scientifically reduces cardboard damage and ensures cardboard quality.

·The original imported American sun company paper feeding wheel box and paper feeding platform, long-term guarantee paper feeding accuracy and paper feeding stability.

·Vacuum transfer printing, accurate transfer cardboard.

·Electrostatic dust removal device, equipped with multi-row brush and super-strong suction fan to remove paper scraps on the surface of the cardboard to improve printing quality.

·Automatic protection device for host motor (the host cannot start when the machine is not locked).

Printing unit (upper and lower unit)

·The whole process of vacuum adsorption conveying cardboard, so that the whole machine to meet the upper and lower printing at the same time, one go. (full servo optional)

·The printing phase adjustment is driven by a servo motor, which has higher printing accuracy and faster speed.

·The surface of the paper feeding wheel is ceramic, which increases wear resistance and prolongs life.

·With quick cleaning function.

·Optional imported brand scraper ink supply system: the main body of the scraper cavity is made of non-metallic special material, which will never rust and is easy to clean; the scraper blade can be quickly replaced. (Optional)

Drying unit (upper and lower unit)

·According to the width of the cardboard, the infrared tube can be controlled in sections to save energy.

·The infrared drying method can quickly dry the moisture on the surface of the printed matter, avoid the drag phenomenon that occurs during die cutting, and also effectively improve the printing speed of the product and ensure the quality of the gloss.

·There is a paper jam sensor to prevent fire.

Independent glazing unit

·Choice of water-based varnish orUV The varnish is carried out with varnish.

·Further enhance the cardboard surface wear and printing effect,Make cartons more environmentally friendly and safer.

Die-cutting unit (optional independent servo)

·Independent servo drive die-cutting unit, high precision, so that every time the die-cutting are clean.

·The rubber pad roller compensation is driven by an independent motor to control the speed of the rubber pad roller, and the compensation range is ±3.5mm.

·rubber pad roller machinery50mm Reversing walking traversing structure.

·The rubber pad roller cuts the flat structure to keep the surface of the rubber pad flat.

Main technical parameters

|

Model |

T-GC920 |

T-GC924 |

T-GC1224 |

T-GC1228 |

T-GC1628 |

T-GC1632 |

T-GC1636 |

|

Maximum mechanical speed (sheets/min) |

300 |

300 |

250 |

230 |

180 |

180 |

160 |

|

Maximum paper feed size (mm) |

900 × 2000 |

900 × 2400 |

1200 × 2400 |

1200 × 2800 |

1600 × 2800 |

1600 × 3200 |

1600 × 3600 |

|

Minimum feed size (mm) |

270 × 600 |

270 × 600 |

320 × 600 |

320 × 600 |

450 × 600 |

450 × 600 |

450 × 600 |

|

Sheet size (mm) |

1200 × 2000 |

1200 × 2400 |

1500 × 2400 |

1500 × 2800 |

1900 × 2800 |

1900 × 3200 |

1900 × 3600 |

|

Maximum printing area (mm) |

900 × 1960 |

900 × 2360 |

1200 × 2360 |

1200 × 2760 |

1600 × 2760 |

1600 × 3160 |

1600 × 3560 |

|

Minimum slotting interval (backcut: mm) |

240 × 65 × 240 × 65 |

240 × 65 × 240 × 65 |

260 × 65 × 260 × 65 |

260 × 65 × 260 × 65 |

260 × 65 × 260 × 65 |

260 × 65 × 260 × 65 |

260 × 65 × 260 × 65 |

|

Minimum slotting interval (positive cutter: mm) |

130 × 130 × 130 × 130 |

130 × 130 × 130 × 130 |

130 × 130 × 130 × 130 |

130 × 130 × 130 × 130 |

130 × 130 × 130 × 130 |

130 × 130 × 130 × 130 |

130 × 130 × 130 × 130 |

|

Maximum slotting depth (mm) |

250 |

250 |

300 |

300 |

400 |

400 |

400 |

Due to technical needs, product specifications or mechanical structure of a small amount of improvement, without notice, subject to contract parameters.

Product Consulting

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.

Recommend Products